One of the most crucial concepts we teach during our onboarding process is the 8 Wastes. These wastes are key contributors to inefficiency, and learning to identify and eliminate them empowers our team to continuously improve.

Here is an overview of the 8 wastes:

Defects: Errors that require rework or cause products to be scrapped. Defects slow down production and reduce overall quality.

Overproduction: Creating more products than needed, leading to excess inventory and wasted resources.

Waiting Time: Time lost when people, materials, or machines are idle. Waiting delays workflow and reduces productivity.

Non-Utilized Genius: Underutilizing the talent, skills, and creativity of team members. Encouraging innovation can unlock potential solutions and improvements.

Transportation: Unnecessary movement of materials or products across long distances. This waste adds time and costs to production without adding value.

Excess Inventory: Excessive inventory ties up space and capital, leading to storage challenges and potential waste if items become obsolete.

Wasted Motion: Unnecessary movement by employees, such as excessive walking to retrieve tools or materials, adds fatigue and reduces efficiency.

Extra Processing: Performing more work or adding more features than necessary, often because of unclear specifications or poor design.

At TrippNT, we actively practice waste identification to continuously improve our operations. Each day, we dedicate 15 minutes for every team member to identify waste in their workspace or process and “fix what bugs them.”

We have found that waste identification and problem solving are like a muscle. Once you start improving you find that you have more time and less frustration the next day. This daily habit strengthens problem-solving skills, leading to profound changes in how we work. As this muscle grows, it is almost impossible to see waste and not want to do something about it.

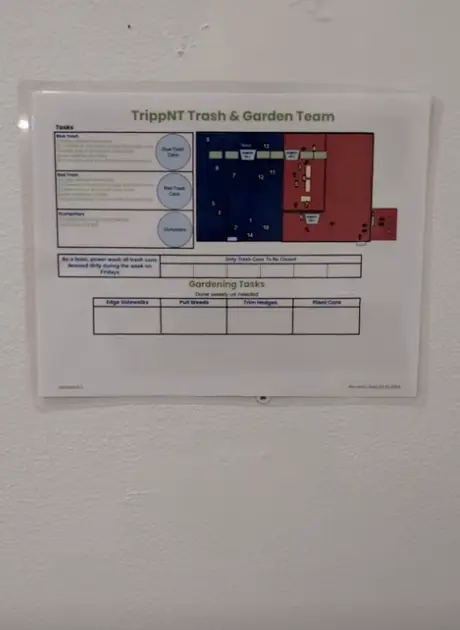

A great example of this is when our Trash and Garden Cleaning team streamlined their workflow by designating a spot for their gloves. Instead of walking across the shop to retrieve them each day, they now have the gloves within easy reach, saving time and reducing frustration. By embracing waste identification and practicing improvement daily, we not only enhance our work environment but also become better problem-solvers in all aspects of life.

Before

After

At TrippNT, we make it a priority to record and share our improvements to inspire innovation and collaboration. By documenting our progress, we not only motivate ourselves but also encourage others to engage in problem-solving and contribute fresh ideas.

You can follow our continuous improvement journey on the TrippNT Improvement Channel, where we showcase our team’s innovative solutions and share practical insights. We hope our experiences spark new ideas for you and your team as well!